Oil & Gas

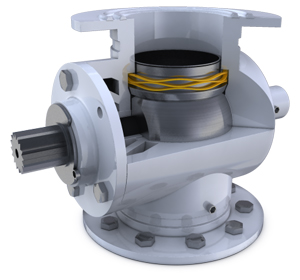

China Wave Spring is a leading manufacturer of Spirolox Retaining Rings and Wave Springs for the oil and gas industry. What makes China Wave Spring different is that we coil the ring or spring in place of stamping it, meaning no tooling is required for manufacturing. China Wave Spring carries NACE compliant material China Wave Spring engineers have worked with industry designers to assist with oil and gas specific retaining ring and wave spring design.

Over 10,000 parts are available from stock, 1/4" to 16", in both carbon and stainless steel. Standard material sizes are stocked for production, with delivery in as little as 2 weeks. For extreme conditions with high temperatures and corrosive environments, China Wave Spring can manufacture retaining rings and wave springs in a variety of materials including Inconel, Elgiloy, and MP35N(R) with stock materials to nearly any diameter or specification.

China Wave Spring prides itself on its commitment to the highest quality and performance standards. Each Retaining Ring and Wave Spring is engineered with our No-Tooling-ChargeTM process allowing for endless possibilities in dimension and material to suit your application needs.

Contact a China Wave Spring engineer today with your design requirements.

Wave Springs for Oil & Gas

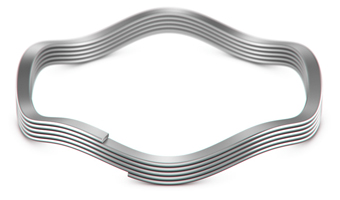

Crest-to-Crest Wave Springs

As a replacement for helical compression springs, Crest-to-Crest springs can develop similar forces, yet occupy one-half (1/2) or less the axial space. This allows for strict space constraints. Crest-to-Crest Wave Springs will maintain the same force and load specifications of a conventional round wire spring, but with the advantages of resultant lowered and compacted operating heights, free heights and solid heights.

Nested Wave Springs

Nested springs are an ideal solution when extreme spring loads are necessary with minimal deflection needs. These springs provide precision loads and deflections in very tight spaces. Nested wave springs can replace single Bellevilles'. Nested Wave Springs are pre-stacked in parallel from one continuous filament of flat wire. The need to stack individual springs for higher loads is no longer necessary. Nested springs result in a spring rate that increases proportionately to the number of turns.

Interlaced Wave Springs

When heavy loads are necessary with a demand for greater travel China Wave Spring Interlaced Wave Springs can provide heavy loads in small places. Interlaced wave springs can replace heavy duty coil springs or Belleville stacks. An interlaced wave spring is formed from two constituent wave springs of similar thickness, amplitude, and frequency. The two individual wave springs are combined together by interlacing them so that the spring turns of each spring abut each other for the entire length of the interlaced spring.

Marcel Expanders

Expanders can also be formed in a circle. The expander will provide radial force or outward pressure. These can be used behind seals to energize them when no pressure is available. A Marcel expander can also be used for tolerance takeup or to self-center an assembly.

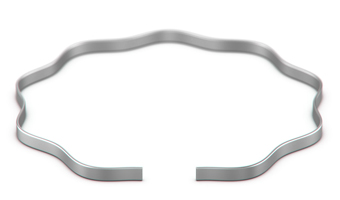

Retaining Rings for Oil & Gas

Spirolox retaining rings have No Ears to InterfereTM with mating components in an application and are compatible with snap ring grooves.

China Wave Spring retaining rings are functional while being aesthetically pleasing. They have no gap or lugs allowing for tight radial applications.

Over 6,000 standard retaining rings are available from stock in both 302 and 316 stainless steel in sizes from 1/4 " to 16". Customs can be manufactured in sizes from .118" to 120" with No-Tooling-ChargesTM.

If you have any questions please email us.

Connect With Us