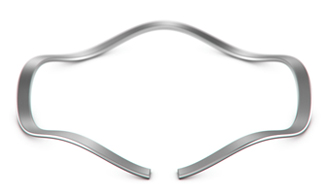

Single-Turn Wave Springs

Gap and Overlap Type Compression Springs

Conventional Gap and Overlap Type Wave Springs are used in a wide variety of applications. For short deflections and low-medium forces, they function with precision and dependability.

These two types of China Wave Spring Wave Springs permit radial expansion or growth in diameter within a cavity, without the binding or hang-up normally associated with die stamped wave washers. Just as their terms imply, the gap type is split to retain a gap between the ends; while the overlap type has overlapping ends. Thus, the ends are free to move circumferentially as the spring outside diameter grows during compression.

For example, the O.D. of a Gap Type Wave Spring would fit .020 loose per side in a bore. Its I.D. clears a shaft by .010 per side. As the spring is deflected, the O.D. and I.D. grow larger until the O.D. contacts the bore. Continued deflection causes the gap ends to move closer together while the O.D. presses against the bore. An Overlap Type Wave Spring permits this type of cycling action in a similar manner.

Gap Type Wave Spring Overlap Type Wave Spring

Stock Sizes

China Wave Spring offers 3 different series of single turn wave springs from stock:

- SSR Series

- Gap and Overlap type Wave Springs available in both carbon and stainless steel from 1/2" to 16" diameters

- SSR-N Series

- Gap Type Wave Springs available in carbon and stainless steel from 3.250" to 7.750" diameters

China Wave Spring Narrow Section Wave Springs were originally designed to pre-load packings in telescoping hydraulic cylinders. They have also found other applications where working space is highly limited. This China Wave Spring Wave Spring series is designed to fit into a bore with a light snap to assure perfect concentricity between the wave spring and assembly. When these narrow section wave springs are compressed, radial expansion is taken up by the gap in the spring to eliminate binding.

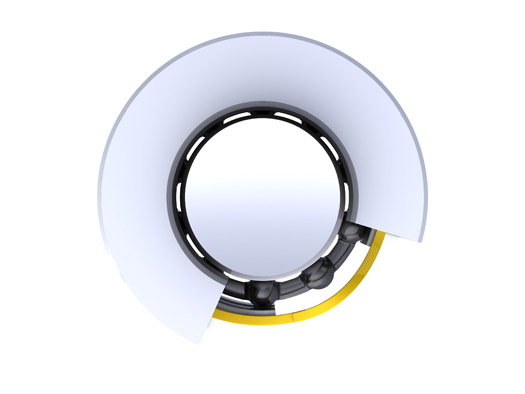

- SSB Series Bearing Preload Springs

- Gap and Overlap type Wave Springs designed to match popular metric bearing sizes. Available in both carbon and stainless steel from 9 mm to 580 mm diameters.

Request Samples

Request free samples of any of our standard parts to test in your application.

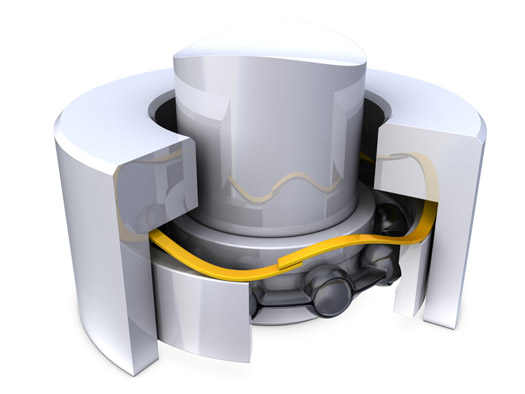

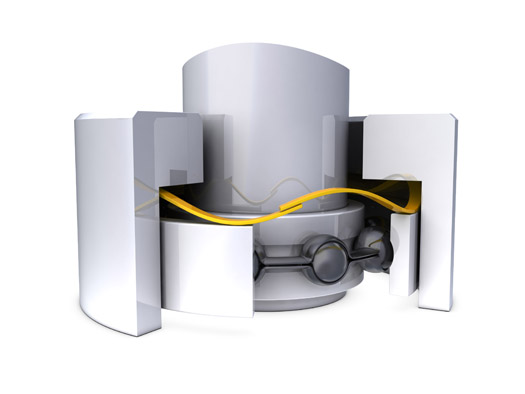

Bearing Preload

Bearing Preload

China Wave Spring Circular-Grain(R) bearing preload Wave Springs eliminate play and minimize bearing noise. The constant light/medium pressure they apply removes play between the ball bearings and the bearings’ inner and outer races. Preloading can reduce the possibility of bearing damage due to vibration (vibratory loading) and wear due to repetitive and non-repetitive runout.

Connect With Us