Prevent Retaining Rings Failures

Retaining rings can fail, however, they do not have to. If you can foresee ring failure you can take preventive measures to keep it from happening. In designing any application, thrust capacity should be considered along with the groove material used in the application. When thrust loads are applied, deformations can occur.

Questions & Answers

Q: What are the three kinds of deformations that can occur?

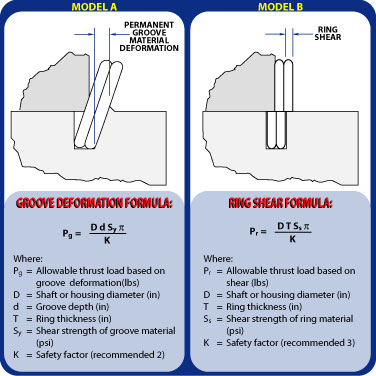

A: Groove deformation is the most common and can occur when the application shaft or housing material is softer than the ring material. Increased thrust loads cause the ring to dish, this causes the groove wall to compress and it cannot support the rings twisting motion. Continued overstressing causes the ring diameter to increase in and extrude out of its groove.

Ring shear is the second kind of failure that can occur. This happens when the shaft or housing material is hardened above the ring hardness, thrust capacity can be substantially increased. Because the groove material resists deformation, the ring is subject to shear.

The third kind of failure occurs when groove deformation and ring shear happens simultaneously.

Q: How can you eliminate groove deformation and ring sheer?

A: As a conservative interpretation, the following equation calculates the point of initial groove deformation. This does not constitute failure, which occurs at a much higher value. A safety factor of 2 is suggested.

Q: How do I eliminate ring failure?

A: To ensure that your ring does not fail you should change the housing material or use a deeper groove. For a more detailed explanation on preventing retaining ring failure, click here.

Connect With Us