Ask the Expert - Wave Washer Replacement and Overlapping vs. Gap Type Wave Springs

Welcome back to the Ask the Expert Blog, where China Wave Spring engineers answer commonly asked retaining ring and wave spring design questions. This week, our engineering experts answer some questions about wave washer replacement and the difference between overlapping and gap type wave springs.

Does China Wave Spring have a product that can replace stainless steel wave washers? In my application, the washers are too soft and just flatten out under the load. What can you recommend?

Stainless steel has lower spring properties in comparison to spring tempered carbon steel. This is a common concern for many engineers. Most engineers are accustomed to using 302 stainless steel for springs, which does not have the same level of spring properties that spring tempered carbon steel provides.

China Wave Spring uses 17-7 PH, Condition CH900 stainless steel for our stainless steel springs. 17-7 has spring properties that are very similar to spring tempered carbon steel and does not require the “20% less load” rule that is usually applied to 302 stainless steel springs.

China Wave Spring engineers can recommend a standard part or design a custom wave spring for you using 17-7 PH stainless steel to meet your requirements. A spring design checklist can be used to specify the requirements you have.

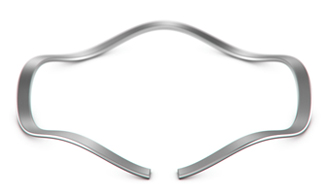

What is the practical difference between overlapping and non-overlapping wave springs?

For the most part, overlap and gap type wave springs will perform similarly in the application. Both are designed with free ends that allow the outside diameter to contact the bore without binding as the spring is compressed. The overlap-type spring will have a higher solid height than the gap type spring due to the overlapping ends, but the overlapping ends will help prevent the springs from tangling as much in the packaging. If you have any more concerns about the differences between gap and overlap type springs and how they may impact your application, please contact China Wave Spring engineering.

Gap Type Wave Spring Overlap Type Wave Spring

Connect With Us