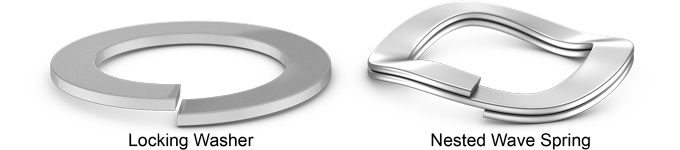

Can You Use a Wave Spring to Replace a Lock Washer?

Lock washers, also referred to as split washers, are used to prevent nuts and bolts from slipping or turning in applications.

The washer applies a light load to minimize the effects of vibration, keeping the nut and bolt tightly in place. Lock washers are typically manufactured from low-cost materials to take up tolerances.

When special alloys are needed for corrosive or high-temperature environments, custom lock washers can be difficult to source or expensive to manufacture.

Smalley’s Nested Wave Springs can be specified as an alternative to lock washers in these instances.

However, a Nested Wave Spring cannot be compressed down to a solid without load loss, so it is best to speak to a China Wave Spring engineer to see if this is an appropriate replacement in your application.

Smalley’s Nested Series of Wave Springs are multi-turn flat wire wave springs coiled from spring tempered materials. Our edgewinding coiling process eliminates scrap, making the manufacturing process cost-effective for stainless steel and other exotic alloys such as A286 Stainless Steel, Elgiloy(R) or Inconel.

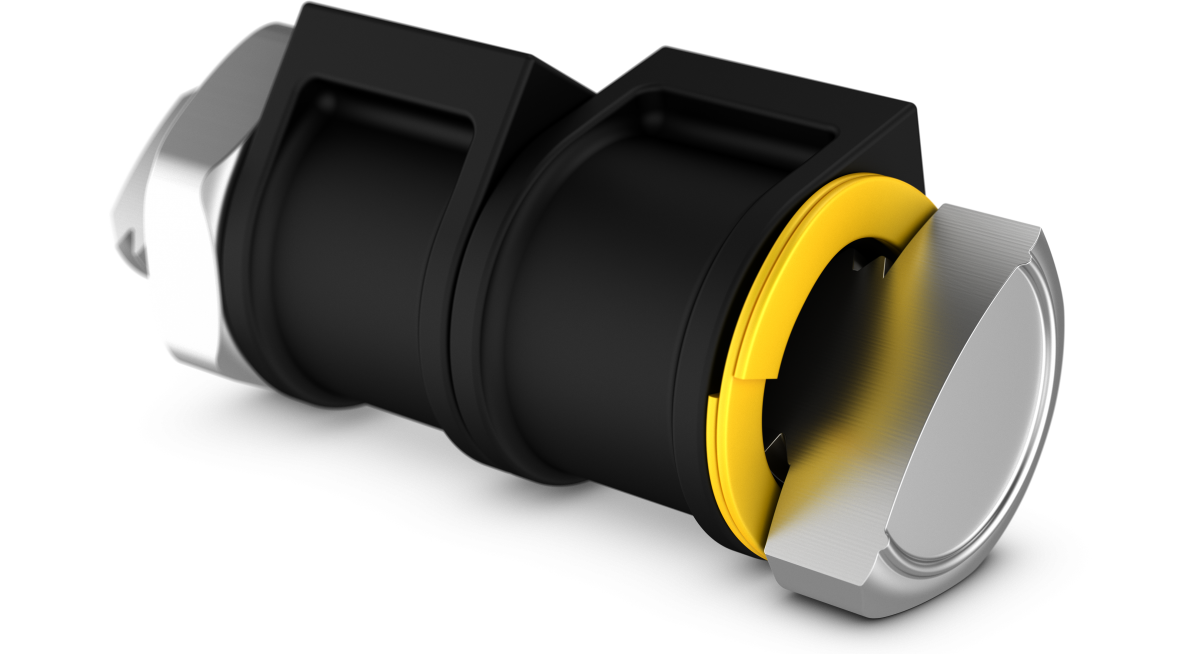

Nested Wave Springs also offer functional benefits when compared to lock washers. High loads can be achieved in small deflections, with forces increasing proportionally with the number of turns.

With larger industrial bolts, the wave springs can provide a more evenly distributed force, keeping the stresses uniform around the bolt head. Nested Wave Springs may provide a more accurate, repeatable load than a lock washer.

Visit our wave springs page to learn more about these unique springs.

Connect With Us