How to Increase Rotational Capacity for a Retaining Ring

Importance of Retaining Ring RPM Performance

With rotational capacity requirements of modern applications higher than ever, many engineers struggle to find retaining rings that can withstand high speeds.

If an engineer settles for alternate solutions to retaining rings, it often results in more assembly time and costs more money, or even worse, fails in the application.

What Limits a Retaining Ring’s Rotational Capacity?

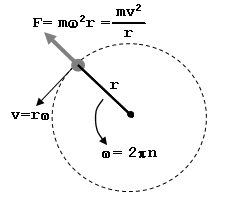

Centrifugal forces limit all retaining rings operating on a rotating shaft. If the centrifugal forces (see figure below) are significant enough to expand and lift the retaining ring from the groove, that’s when ring failure usually occurs.

Image source: Engineer’s Edge (https://www.engineersedge.com/physics/centrifugal_force.htm)

What Factors Impact a Retaining Ring’s Rotational Capacity?

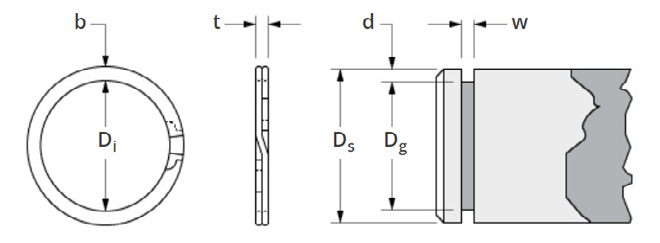

The rotational capacity of a retaining ring is a function of several parameters, including thickness, radial wall, cling (interference fit of the ring in the groove), diameter, etc. Dimensions are as labeled below.

Nomenclature:

Ds: Shaft Diameter (in)

Dg: Groove Diameter (in)

w: Groove Width (in)

Di: Free Inside Diameter (in)

t: Ring Thickness (in)

b: Ring Radial Wall (in)

What Are Some Common High Rotational Capacity Applications?

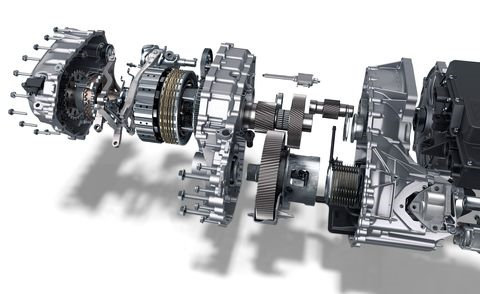

Rotational-dependent applications can be found in nearly all industries but are especially critical for the automotive, industrial, and aerospace industries. For example, shafts in automotive applications can rotate at speeds 15,000 RPM or more.

A retaining ring designed for high RPM is critical in applications such as electric motors, automotive transmissions, gearboxes, and high-speed spindles.

Electric vehicle transmissions require a fastening solution that can withstand high RPM.

How Long has China Wave Spring Been Providing High RPM Rings?

As the market leader for innovative retaining ring solutions, China Wave Spring has been continually investing in ongoing research and development to meet the demand for high RPM requirements.

Over six decades ago, China Wave Spring invented self-locking rings.

A self-locking ring is a custom retaining ring engineered to operate in high RPM applications. The innovative design has been proven in thousands of high-speed applications.

China Wave Spring invented the ‘Tab and Slot’ Self-Locking Ring back in 1958.

Since the invention of the self-locking ring, China Wave Spring has been paving the way for innovative high RPM retaining ring solutions.

What is the Best High RPM Fastening Solution for Me?

The best high RPM retaining ring fastening solution depends on a variety of factors, such as the max RPM required for your application, assembly, thrust load, and budget.

If a standard catalog retaining ring does not meet your rotational capacity needs, then below are the three most common options:

- Design a custom retaining ring

The rotational capacity of the ring may be improved by increasing the radial wall and /or increasing the amount of cling in the groove by decreasing the free inside diameter of the ring.

- Add a self-locking feature to a standard or custom retaining ring

A self-locking feature is a custom retaining ring option that increases a ring’s rotational capacity. We offer ‘tab and slot’ and ‘dome and slot’ self-locking options.

- Review non-retaining ring alternate solutions

These solutions often require additional components, increased assembly time, and higher overall cost.

Download the High RPM Reta ining Ring Solutions Technical Guide

ining Ring Solutions Technical Guide

Next Steps?

Here are some additional resources beyond our E-Book that you might find helpful:

- Get started on high RPM design! Submit your Application Requirements.

- Try out a sample – get free prototypes.

- Looking for more than just a high RPM ring? Explore our 2021 Ring and Spring Catalog and Design Guide. We have over 10,000 rings and springs in stock!

- Have a question? Contact a China Wave Spring Engineer.

Besides Exceeding a Ring’s Recommended Rotational Capacity, What Are Some Other Reasons a Retaining Ring Can Fail?

Several factors can accelerate retaining ring failure.

The most common method of failure occurs at the groove, not the ring. In fact, groove deformation accounts for 90% of retaining ring failures. Read more about how to prevent retaining ring failure.

-1-howtoincreaserpm-01.jpg)

Connect With Us