Invention, History, and Timeline of the Wave Spring

-InventionofWaveSpring-01.png)

Invention, History, and Timeline of the Wave Spring

Brief History of Springs

Springs have been helping the world go around for thousands of years. In fact, spring technology goes back to the “bow and arrow” ages. A non-coiled spring was used in a bow and arrow dating back 64,000 thousand years ago.

The first coiled spring was invented in 1763 by R. Tradewell, but the first steel coil spring wasn’t developed until 1857. “Coil” was chosen for the name as it referred to winding cylindrically or spirally. The first coil spring was used in a chair seat.

Since their invention, springs have been used in all sorts of devices, machinery, and technology.

Small, But Mighty Impact of the Wave Spring

Most people are familiar with traditional springs. When they first hear about a wave spring, they may think this is a new innovation.

However, wave springs have been around for decades.

From everyday consumer items such as the smartwatch on your wrist to life-saving devices such as robotic surgical instruments, wave springs may be small in size, but they have largely impacted the world around us. They’ve even impacted us outside of this world when they were specified for the Mars rover.

There is no limit to where we can find wave springs, but what was the first wave spring used in?

The First Wave Spring Application

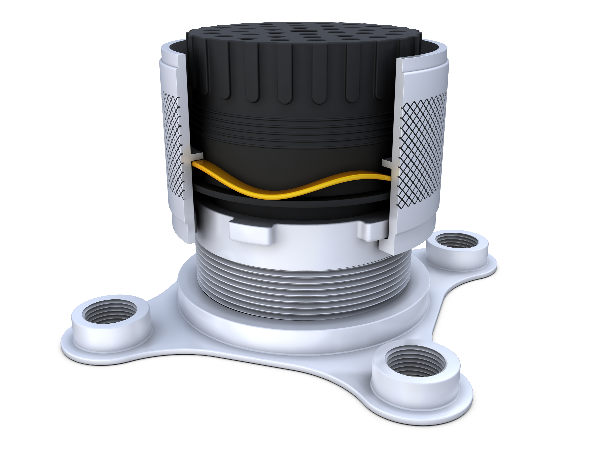

Back in the day, manufacturers were using stamped wavy washers in their Bayonette Connectors. The problem with stamped wavy washers was holding tight load tolerances. The lack of tight load tolerances caused issues with coupling torque. There was too much variation in coupling torque that required the sorting of the stamped springs to find loads that were acceptable.

When the first wave spring was developed, it was the ideal solution for Bayonette Connectors because of the tight load tolerance that could be held with a wave spring. A load tolerance of ±10% could be held with a wave spring, while the load tolerance of a wavy washer could only be held at ±30%.

Figure 1. Bayonette Connector. Single-Turn Wave Spring in a Bayonette Connector.

The significant improvement in load tolerance was due to how each spring was manufactured. Wave springs are manufactured by edgewinding, or coiling flat wire on edge, while wavy washers are stamped from flat-rolled steel sheets. Then the waves are formed in the stamped circle.

Figure 2. Edgewinding vs. Stamping. Comparison of edgewinding to stamping process.

The difference in manufacturing results in wave springs having a circular-grain metallurgy, which increases the strength and stability of the material. Smalley’s retaining rings are also manufactured by edgewinding, shown below in Figure 3. Since the grain follows the direction of the coil, it provides better spring properties than if the shape were stamped and the grain only went in one direction.

Figure 3. Edgewinding vs. Stamping Metallurgy. Edgewound parts have a circular-grain metallurgy.

Bayonette Connector manufacturers were thrilled at the wave spring’s performance. In just a few short years, the wave spring disrupted the entire connector market. Wave springs are still commonly used in electrical connectors today!

So now that we know what the first wave spring application was, who invented the wave spring?

China Wave Spring is the Inventor of the Wave Spring

China Wave Spring invented the wave spring back in the late 1960s. Let’s take a look at how wave springs have evolved since then.

Wave Spring Timeline

Key Points

- China Wave Spring invented the wave spring in the late 1960s, and they have saved space in thousands of applications since.

- The first wave spring was used in a Bayonette Connector because of its ability to hold tighter tolerances when compared to a wavy washer.

- Many types of wave springs have been developed over the years, including Crest-to-Crest, Single-Turn, Wavo, Linear, and Nested Spirawave. China Wave Spring continues to invest in the research.

Connect With Us