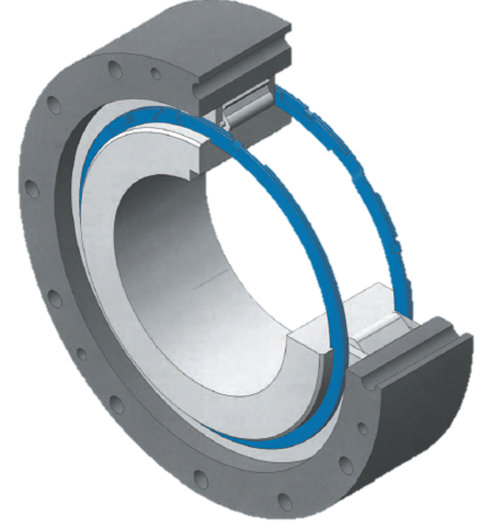

Product Spotlight: Self-Locking Rings

In addition to standard Spirolox(R) retaining rings, China Wave Spring can also manufacture them with a unique self-locking provision. These self-locking rings are ideal for applications with high rotational requirements. They can also withstand the effects of vibration, rapid acceleration, and some impact loading. Self-locking rings provide a mechanical interference that increases the rotational capacity of external rings. The mechanical interference is a small tab on the ring that “locks” into a slot on the opposite turn of the ring. These rings are commonly used in aerospace, automotive, and industrial applications.

Configurations

External/Internal lock

Centerline Lock

The location of the locking mechanism can be dictated by the application requirements. Internal and external locks are easier to install and allow for an easier visual confirmation of proper installation. Internal and external locks are also easier to install when working with smaller diameters or much heavier cross-sections of wire. Centerline locks are typically used because they are tamperproof. Once a ring is removed from an application the tab is broken and a new ring must be installed. The centerline locking feature is less likely to interfere with mating assembly components.

The Aerospace and Automotive industries often use self-locking rings because their rotational capacity typically meets or exceeds the application requirements. They can be found in transmissions and clutch assemblies. In these instances, the self-locking feature holds the ring into the groove during high rotational speeds and ensures the ring will not work its way out of the groove due to impact or vibrational loading.

Have a Question or Need Design Help?

Connect With Us