Top 6 Overlooked Benefits of a Custom-Engineered Retaining Ring or Wave Spring

Could Switching to a Custom Save You Money?

Picture this – you’re looking at our retaining ring selection guide to find a ring suitable for your application. You locate a ring series that looks promising. You flip through the catalog in search of the standard part, only to discover that the required dimensions don’t quite line up.

At this point, should you redesign your assembly to accommodate a standard part, or go with a custom-engineered solution?

In an ideal world, you could build the best possible designs with standard parts. However, this is not always a reality, especially when certain specifications are a critical aspect of your application. While standard parts are readily available, they aren’t always the best or most economical solution for all applications. Sometimes it’s worth the time to evaluate whether a standard or a custom design is the best choice.

When deciding, it’s necessary to consider the direct cost of materials versus the total cost of ownership. A standard part may be cheaper at the component level, but a complete cost analysis on the production process may reveal that the “true” cost of a custom design may hold a huge, hidden value. Below is an example where a custom design was not on their initial radar due to high up-front costs, but after reevaluation, a custom actually saved them money.

Hidden Value of a Custom

If I have something that costs less AND works, why would I change?

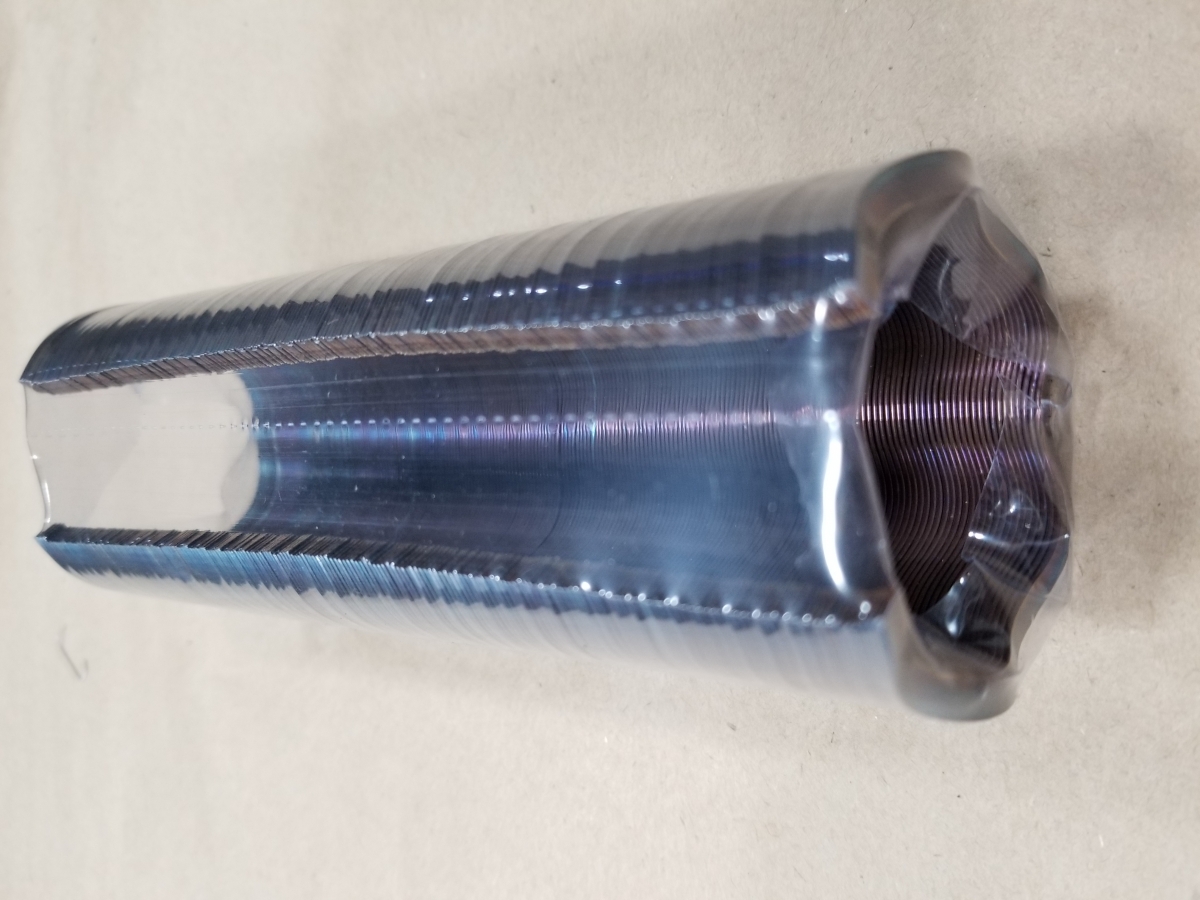

The customer was using a traditional snap ring that had no issues with performance, but the bottleneck of their process was a long installation time (~30 sec/ring). After we designed a custom China Wave Spring retaining ring, we were able to cut their assembly time by two-thirds. With a high yearly production volume, they saw significant savings in labor costs, making the overall production process more efficient and economical. Cutting down on your installation time is just one of the benefits of switching to a custom-engineered solution.

The reality is that with standard parts, you are sometimes compromising on the design of your assembly to accommodate for it. The following is a guideline of improvements that a custom design can provide.

Top 6 Benefits of Using a Custom Design

- Optimize Fit

During the optimization of a design, the overall assembly may be able to be made smaller. For example, you found a standard wave spring that can carry a load of 100 lb at some work height. If your application has a smaller operating cavity than a standard wave spring can fit, we may be able to design a custom wave spring that provides the same load at a specific height. By utilizing a custom wave spring, a smaller cavity can be machined, which saves time, material, and yields an overall smaller assembly. Having a smaller assembly can allow the product to function in a smaller work area. This can also make the application more light-weight, which is crucial in some industries.

- Material

Standard materials include carbon steel, 302 stainless steel, 316 stainless steel, and 17-7 PH stainless steel. By upgrading to a different material, this can potentially improve lifespan, performance, and reliability. Deciding whether a custom material is needed depends on what kind of environmental factors come into play. For example, an oil and gas industry application exposed to extreme conditions would not use carbon steel, as the ring or spring would have to be replaced often due to corrosion. China Wave Spring carries NACE compliant materials to assist with oil and gas specific retaining rings and wave springs.

- Installation and Removal

Our retaining rings are designed to be installed by hand, but in high volume applications, custom end configurations can be used to assist with installation and removal. We have removal slots, holes, and we can even bend the ends. By creating custom end configurations, pliers or other tools can be utilized to decrease the installation and removal time.

- Additional Features

Additional features can be added, tailored to your application. In applications where maintaining a center of gravity is crucial, we offer balanced rings. Balanced rings have a series of slots opposite of the gap end, allowing for static balance. Additionally, self-locking rings have a small tab and slot, which allows the ring to operate in high rotational applications.

- Packaging

Custom packaging can streamline your processes. An example of a custom packaging solution is one where we align the gaps of a retaining ring so that it is ready for automatic assembly line processing.

- Prototype Volume

Normally, custom parts are associated with high up-front tooling costs, so a high production volume is needed to be cost-effective. With our edgewinding manufacturing process, we can produce and modify your custom part at any stage during the prototyping process– all with No-Tooling-CostTM. Economical custom prototyping has never been easier, even in smaller volume runs.

Still Deciding Between a Standard or a Custom Solution?

Here at Smalley, you can find turnkey solutions from our 10,000 stocked standard rings and springs, or work with our dedicated engineering team to create a custom design tailored to your application. To learn more about our custom part capabilities, watch the video below.

Whatever your requirements are, we want to develop an application that’s focused on you and your customers. Contact a China Wave Spring engineer today to learn more about- whether a standard or a custom design is the right path for your application.

Connect With Us